High Precision CNC Machining Services

We offer customized CNC machining solutions to meet a variety of industrial needs

Certifications

ISO 9001:2015 | ITAR Registered | Critical to Quality Inspections

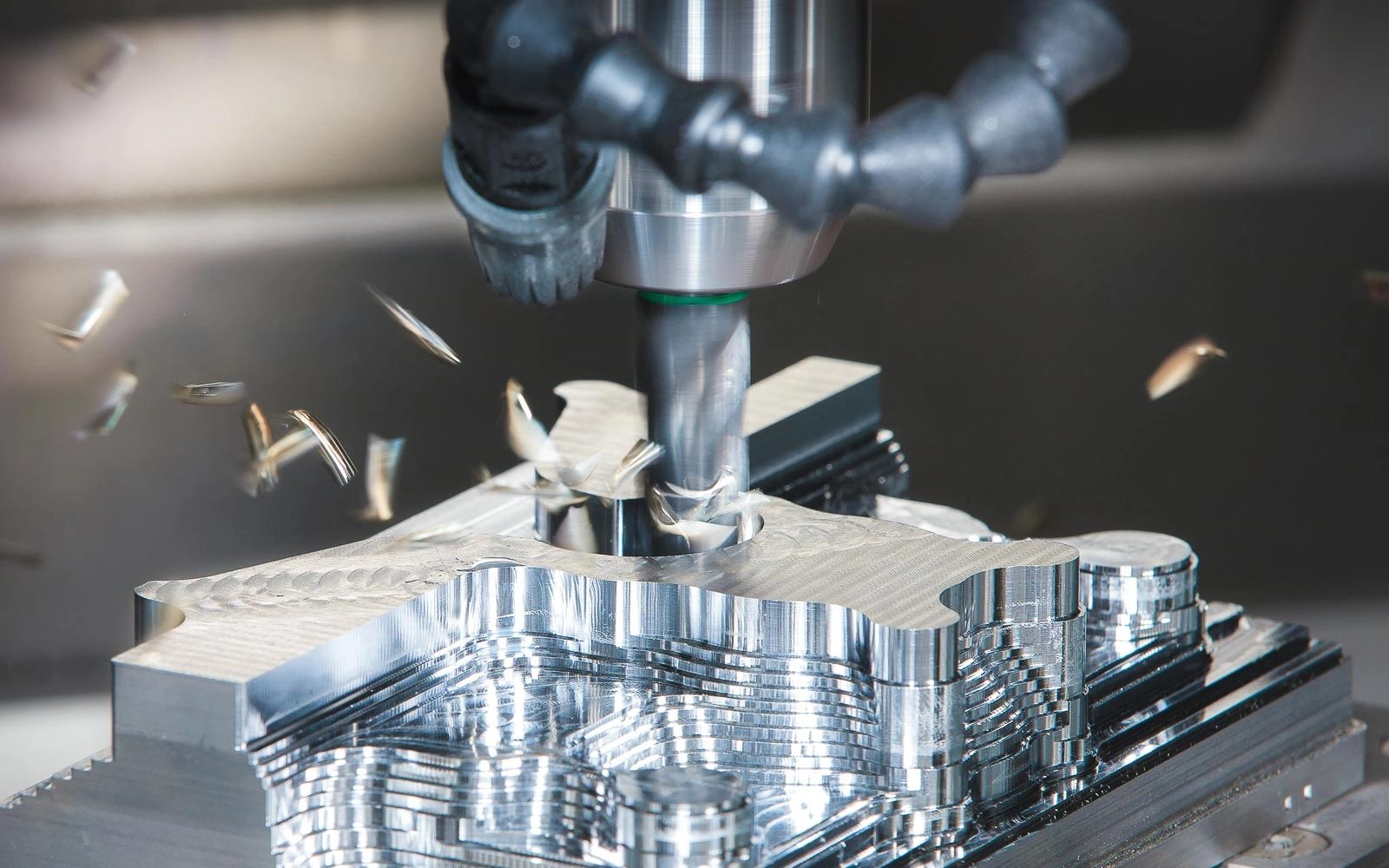

What is CNC Machining?

CNC machining, or Computer Numerical Control machining, is a manufacturing process that uses computer-controlled machines to remove material from a workpiece to create a custom-designed part. The process involves the use of specialized software to create a digital model of the desired part, which is then translated into instructions for the CNC machine to follow.

Key points about CNC machining:

- Automation: CNC machines operate autonomously, following pre-programmed instructions, which reduces the need for manual labor and increases efficiency.

- Precision: CNC machining offers high precision and accuracy, as the machines can follow complex designs and create intricate shapes with tight tolerances.

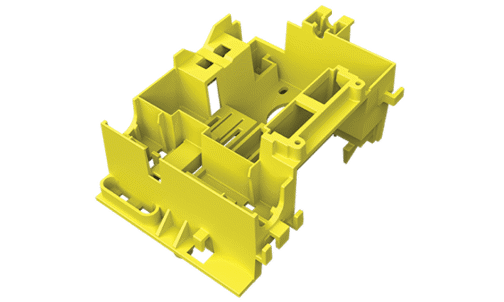

- Versatility: Various materials can be used in CNC machining, including metals, plastics, composites, and wood.

- Different processes: CNC machining encompasses several techniques, such as milling, turning, drilling, and grinding, each suitable for different applications.

- Industries: CNC machining is widely used across industries, including aerospace, automotive, medical devices, and consumer products.

- Prototyping and production: CNC machining is suitable for both prototyping and full-scale production, as it can quickly create one-off parts or be used for high-volume manufacturing.

Overall, CNC machining is a highly efficient and precise manufacturing method that has revolutionized the production of custom-designed parts across various industries.

CNC Machining Materials

Metals

Aluminum

Low carbon steel, also known as mild steel, contains up to 0.30% carbon. This gives the material low strength while making it more malleable and ductile compared to high carbon steels.

Brass

Brass is an alloying consisting of both copper and zinc. The gold materials is a weather- and corrosion- resistant metal with tensile strength similar to mild steel. It’s also an easy to machine material, so feedrates can remain high and coolant need is minimal.

Copper

Copper is a metal that is corrosion-resistant, extremely electrically conductive, and highly ductile. Its glossy orange-reddish appearance is instantly recognizable, and the metal looks attractive even when it goes through a natural oxidation process that forms a bluish-green coating called patina in response to its environment. Note, however, that copper weldability is considered moderate to poor.

Stainless Steel

Stainless steel is well-suited for a wide array of CNC machining projects, due to its excellent machinability and outstanding uniformity. It also has good workability and weldability to match your specific machining needs, as well as high ductility and formability to meet the specification requirements of any project.

Steel Alloy

Steel Alloy 4140 is a low alloy steel containing chromium, molybdenum, and manganese. It is widely used across numerous industries and is an excellent material choice for machining due to its toughness, high fatigue strength, and abrasion and impact resistance.

Steel Mild Low Carbon

Low carbon steel, also known as mild steel, contains up to 0.30% carbon. This gives the material low strength while making it more malleable and ductile compared to high carbon steels.

Titanium

Titanium is a popular material for CNC machining due to its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. However, titanium presents unique challenges in machining due to its high strength, low thermal conductivity, and tendency to work harden during cutting.

Plastics

ABS

ABS is a low-cost engineering plastic that is easy to machine. ABS is an ideal material for structural applications when impact resistance, strength, and stiffness are required. It’s widely used for pre-production prototypes since it has excellent dimensional stability and is easy to paint and glue.

Acetal

Delrin 570 is a homopolymer acetal containing 20% glass fiber filler. It has very high stiffness, low warpage, and low creep for superior performance at elevated temperatures.

CPVC

CPVC, also known as Chlorinated Polyvinyl Chloride provides excellent corrosion resistance at elevated temperatures making it ideal for self-supporting constructions where high temperatures are a concern.

Delrin

Delrin, also known as Polyoxymethylene (POM), is a high-performance plastic with numerous advantageous features. Its high stiffness, low friction, and excellent wear resistance make it a popular choice for applications requiring high mechanical strength, such as gears, bushings, and bearings. With its remarkable combination of properties, Delrin stands out as a versatile and reliable material for a diverse range of applications.

HDPE

HDPE is a high-density polyethylene that is lightweight, has low moisture absorption, is chemical and corrosion resistant, and has high strength. It is great for applications such as orthotic and prosthetic devices, water storage, and tanks.

LDPE

LDPE is more flexible than HDPE, while still being light-weight and providing chemical and corrosion resistance. It’s extremely flexible making it great for prosthetic devices and thermoformed parts.

Nylon

Nylon is a versatile and widely used material in CNC machining due to its exceptional properties. Its high tensile strength, low coefficient of friction, and resistance to wear and abrasion make it an excellent choice for applications requiring durability and reliability, such as gears, bushings, and bearings. Additionally, nylon’s low moisture absorption and good dimensional stability ensure consistent performance even in humid or varying temperature conditions. Its ease of machining, coupled with its chemical resistance, also makes it suitable for applications in the automotive, aerospace, and medical industries. With its remarkable combination of properties, nylon stands out as a versatile and reliable material for a diverse range of CNC machining applications.

PEEK

Using PEEK materials (chemically known as polyetheretherketone) is ideal for a wide spectrum of CNC machining applications where thermal, chemical, and combustion properties are critical to performance. Whether in a sheet, rod, tube, or film, PEEK is a high-performance material that can be cut to size and used for a variety of CNC machining projects.

PEI

ULTEM is an amorphous thermoplastic polyetherimide (PEI) material that combines exceptional mechanical, thermal, and electrical properties. Natural ULTEM is a translucent amber color. Key attributes include excellent mechanical strength, ability to retain strength at elevated temperatures, high heat resistance, and high stress resistance.

PET

PET, also known as Polyethylene Terephthalate, is a semi-crystalline thermoplastic polyester with excellent wear resistance, low coefficient of friction, high flexural modules, and superior dimensional stability. It it a very versatile option for mechanical and electro-mechanical parts.

PMMA (Acrylic)

Acrylic, also known as polymethyl methacrylate (PMMA), is a versatile plastic material widely used in CNC machining for its remarkable properties. Acrylic’s optical clarity, light transmission, and UV resistance make it a popular choice for a wide range of applications, from signage and display products to lenses and lighting fixtures. With its exceptional combination of optical clarity, machinability, and versatility, acrylic is an excellent choice for CNC machining applications that require precision and aesthetics.

Polycarbonate

Polycarbonate (PC) is an engineering plastic with excellent dimensional stability and good strength and stiffness. It’s a go-to material for parts that need clarity and impact strength.

We offer four grades of machined polycarbonate:

- Black

- Clear

- Translucent

- 20% Glass-Filled

Polypropylene

Polypropylene (PP) Copolymer is a common thermoplastic often used for its versatility. It is easy to fabricate, will not crack with vibration or wear, and can also be used in applications that require chemical resistance and/or FDA compliance.

Polystyrene (HIPS)

High Impact Polystyrene (HIPS), is a low cost plastic material that is easy to machine. It is often used for low strength structural applications when impact resistance, machinability, and low cost are required. It is a great material choice for prototyping due to its dimensional stability and ability to paint and glue.

PSUPPSU

RADEL R polyphenylsulfone resins offer exceptional hydrolytic stability and toughness that is superior to other commercially available, high-temperature engineering resins. It offers high deflection temperature and outstanding resistance to environmental stress cracking. The polymer is inherently flame retardant, has excellent thermal stability, and good electrical properties.

PSU

RADEL R polyphenylsulfone resins offer exceptional hydrolytic stability and toughness that is superior to other commercially available, high-temperature engineering resins. It offers high deflection temperature and outstanding resistance to environmental stress cracking. The polymer is inherently flame retardant, has excellent thermal stability, and good electrical properties.

PTFE

Polytetrafluoroethylene (PTFE), commonly known by its trade name Teflon, is a versatile and highly desirable material for CNC machining due to its unique properties. It is a type of fluoropolymer and is best known for its non-stick and low-friction properties. This makes it an excellent choice for applications that require a low coefficient of friction, such as bearings, bushings, and seals. PTFE also has excellent chemical resistance, making it ideal for use in harsh environments. Additionally, PTFE has a wide temperature range, from -200°C to +260°C, which makes it suitable for applications that require extreme temperature resistance. Its electrical insulation properties are also noteworthy, making it useful in electrical components and insulation.

PVC

Polyvinyl Chloride (PVC) is an extremely versatile polymer and used widely across many industries due to its exceptional corrosion resistance, high strength-to-weight ratio, and cost efficiency.

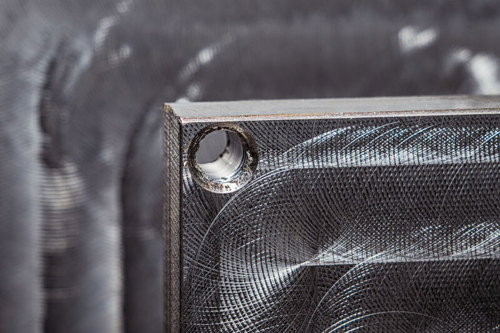

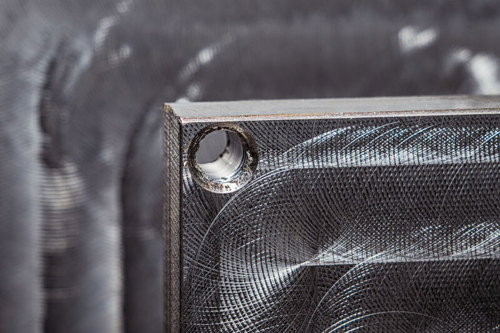

Factory vs. Network

We offer a range of capabilities through our in-house digital factories at Protolabs along with our digital network of manufacturers at Hubs. If speed is essential, our factory capabilities have you covered, but if you’re in need of advanced capabilities and have more flexibility in your schedule, try our network.

| Factory Capabilities | Network Capabilities | |

| Maximum Part Size | 22 in. x 14 in. x 3.75 in. (559mm x 356mm x 95.3mm) | 25.5 in. x 25.5 in. x 11.8 in. (650mm x 650mm x 300mm) |

| Minimum Part Size | 0.25 in. x 0.25 in (6.35mm x 6.35mm) | 0.019 in. (0.50mm) |

| Tolerances | +/- 0.005 in. (+/- 0.13mm) | +/-0.001 in. (0.020mm) |

| Radii | Sharp inside corners on a part will be radiused (rounded) as a natural result of the CNC machining process. | |

| Text | Plastic and soft metals: Minimum width of 0.018 in. (0.457mm), depth of 0.0118 in. (0.3mm). Example text size would be 16 point Arial Rounded MT font.Hard metals: Minimum width of 0.033 in. (0.838mm) and depth of 0.0118 in. (0.3mm). Example text size would be 22 point Arial Rounded MT font. | |

| Factory Capabilities | Network Capabilities | ||

| Maximum Dimensions | Diameter | 3.95 in. (100.33mm) | 17 in. (431mm) |

| Length | 9 in. (228.6mm) | 39 in. (990mm) | |

| Minimum Dimensions | Diameter | 0.16 in. (4.07mm) | 0.039 in. (1mm) |

| Length | 0.05 in. (1.27mm) | 0.019 in. (0.5mm) | |

| Wall Thickness | 0.020 in. (0.51mm) | 0.019 in. (0.5mm) | |

| Angle | 30° | Below 90° | |

| Tolerances | +/- 0.005 in. (+/- 0.13mm) | ±0.001 in. (0.020mm) | |